Unlocking Electric Motors: The Power of Circuit Diagrams

Ever wondered how machines move, how robots dance, or how conveyors tirelessly carry their loads? The secret often lies within a seemingly simple document: the motor control circuit diagram. This isn't just a collection of lines and symbols; it's the blueprint for bringing electromechanical systems to life, from the smallest toys to the largest industrial machinery. So, buckle up as we unravel the mysteries and power contained within these crucial diagrams.

Motor control circuit diagrams, often available as PDFs for easy sharing and printing, provide a visual representation of the electrical connections and components necessary to control the operation of an electric motor. They're the language that engineers and technicians use to communicate the design and functionality of motor control systems. Think of them as the recipe for making a motor do exactly what you want it to do: start, stop, reverse direction, adjust speed, and protect itself from damage.

The history of these diagrams is intertwined with the development of electric motors themselves. Early motor control was simple, often involving just switches and relays. As motors became more complex and integrated into increasingly sophisticated systems, the diagrams evolved to reflect these advancements. Today, they can encompass a wide range of components, from programmable logic controllers (PLCs) to variable frequency drives (VFDs), and often incorporate digital logic and communication protocols.

The importance of a well-designed motor control circuit diagram cannot be overstated. A clear and accurate diagram is essential for troubleshooting, maintenance, and modifications to a motor control system. Imagine trying to diagnose a problem in a complex electrical system without a roadmap. The diagram serves as that roadmap, allowing technicians to quickly identify and resolve issues, minimizing downtime and maximizing efficiency. Furthermore, a comprehensive diagram is crucial for safety, ensuring that the system is designed to operate within safe parameters and prevent hazards.

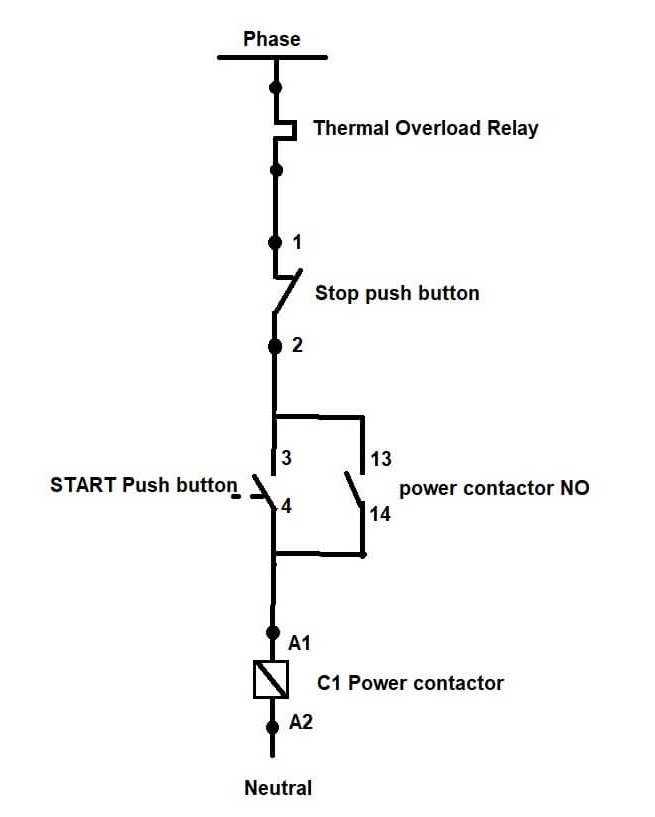

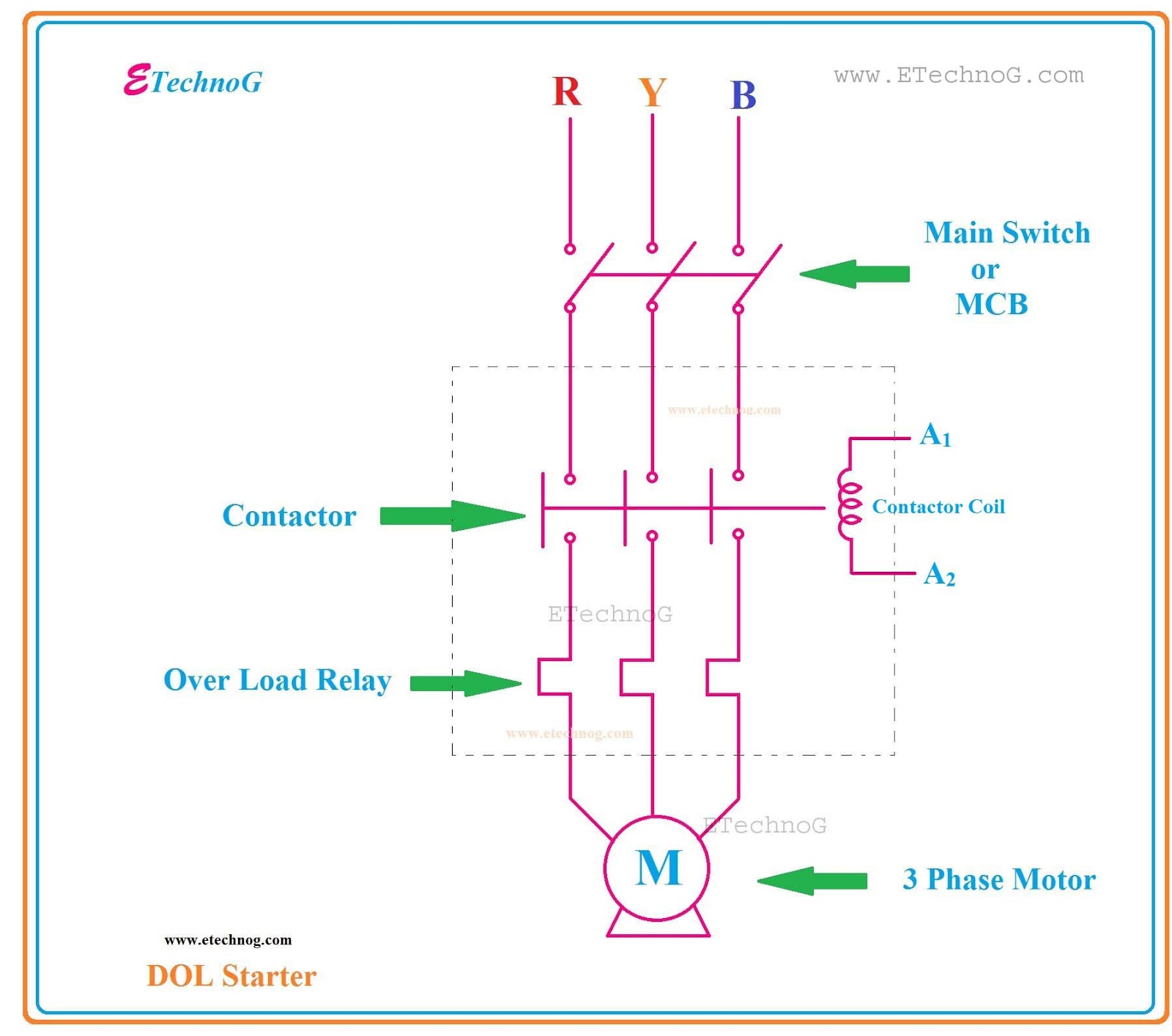

Understanding the basic elements of a motor control circuit diagram is crucial. These diagrams typically include symbols for various components such as motors, switches, relays, fuses, circuit breakers, and control devices. Lines connecting these symbols represent the wiring and flow of electricity within the system. A simple example might be a circuit diagram for starting and stopping a motor using a single start/stop button station. This diagram would show the wiring connections between the button, the motor starter, and the power supply.

A motor control circuit schema simplifies troubleshooting by clearly illustrating the connections. For instance, if a motor fails to start, a technician can consult the diagram to trace the circuit and pinpoint the faulty component. Moreover, these blueprints provide a valuable tool for training new technicians and engineers, allowing them to visualize the intricacies of motor control systems. They are essential for documenting the design of a system, which can be crucial for future upgrades, modifications, or replication.

A detailed step-by-step guide on interpreting motor control schematics would involve identifying the power source, tracing the current path through each component, understanding the function of each component (e.g., relays, timers, overloads), and recognizing the control logic implemented in the circuit.

Advantages and Disadvantages of Using Motor Control Circuit Diagram PDFs

| Advantages | Disadvantages |

|---|---|

| Easy to share and distribute | Can become outdated if the physical circuit is modified |

| Printable and portable | Static, doesn't allow for interactive simulations |

| Can be archived for future reference | May require specialized software to view or edit |

Best practices for creating motor control schematics include using standardized symbols, clearly labeling all components, indicating wire sizes and colors, providing a revision history, and ensuring the diagram is easily readable and understandable.

Real-world examples of motor control circuits include those found in HVAC systems, industrial automation equipment, robotics, electric vehicles, and even simple household appliances like washing machines and refrigerators.

Frequently asked questions about motor control circuits cover topics such as the types of starters used, methods for speed control, protection against overloads and short circuits, and the role of various components like contactors and relays.

Tips and tricks for working with motor control circuit diagrams include using highlighting to trace circuits, keeping a library of common symbols, and referencing relevant industry standards.

In conclusion, motor control circuit diagrams, often disseminated as PDFs, are essential tools for designing, implementing, and maintaining electromechanical systems. Their importance spans across numerous industries and applications, enabling the precise and efficient control of electric motors. Understanding these diagrams empowers engineers and technicians to troubleshoot problems effectively, enhance system performance, and ensure safe operation. From the initial design phase to ongoing maintenance, the motor control circuit diagram serves as the indispensable guide for harnessing the power of electric motors. By mastering the art of interpreting and applying these diagrams, we unlock the potential of electromechanical systems to drive innovation and power the world around us. Explore resources like online forums, technical manuals, and specialized software to deepen your understanding of motor control circuit diagrams and unlock their full potential.

Crafting your discord identity the power of profile pictures

The untold legacy exploring the world of harry potter heir of peverell fanfiction

Tattoos that bloom the allure of daisy tattoos on the arm