Unlocking Efficiency: Your Guide to the Standard SAE Bolt Size Chart

Imagine this: You're in the middle of a project, wrench in hand, ready to secure your masterpiece. But as you reach for a bolt, doubt creeps in. Is this the right size? Will it fit? Suddenly, that surge of accomplishment turns into a frustrating guessing game. This, my fellow builders and tinkerers, is where the humble yet mighty SAE bolt size chart comes to the rescue.

In the world of fasteners, consistency is king. And when it comes to American machinery, automotive work, or even DIY projects around the house, the SAE (Society of Automotive Engineers) system is the reigning monarch. The standard SAE bolt size chart, often tucked away in toolboxes or bookmarked on phones, provides a universal language for bolt dimensions, ensuring that a 1/4-20 bolt in Alabama fits a nut in Alaska with the same reassuring click.

But this chart isn't just a handy reference; it's a testament to the power of standardization. Before its widespread adoption, the fastener world was a chaotic landscape of varying sizes, threads per inch, and materials. This lack of uniformity led to compatibility issues, wasted resources, and more than a few headaches for engineers and mechanics. The SAE, recognizing the need for order, stepped in and established a standardized system, paving the way for the reliable, efficient world of modern manufacturing we know today.

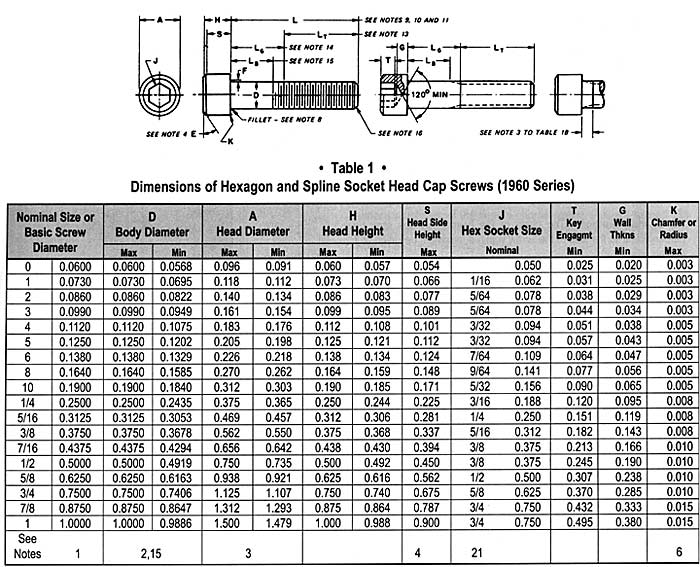

Understanding the SAE bolt size chart is like unlocking a secret code to a world of smooth assembly. Each number and marking on a bolt suddenly transforms from gibberish into a clear set of instructions. The chart lays out the diameter, thread pitch (threads per inch), length, and head type, ensuring you select the perfect fastener for your needs. No more trial and error, no more stripped threads - just the satisfaction of a job well done.

Whether you're a seasoned mechanic, a budding DIY enthusiast, or simply curious about the hidden world of fasteners, this guide will equip you with the knowledge to confidently navigate the SAE bolt size chart. We'll delve into its history, explore its practical applications, and arm you with the tools to tackle any project with confidence.

Advantages and Disadvantages of a Standardized Bolt Size System

| Advantages | Disadvantages |

|---|---|

| Interchangeability and Compatibility | Limited Variety for Specialized Applications |

| Wide Availability and Ease of Sourcing | Potential for Confusion with Other Standards (Metric) |

| Simplified Design and Manufacturing Processes |

Best Practices for Working with SAE Bolts

- Always Consult a Reliable SAE Bolt Size Chart: Keep a chart handy or bookmark a reputable online resource.

- Match Bolts and Nuts Carefully: Ensure the thread pitch and diameter match perfectly.

- Use the Correct Tools: Employ appropriately sized wrenches and sockets to avoid damaging fasteners.

- Apply Proper Torque: Over-tightening can lead to breakage, while under-tightening can result in loosening.

- Consider Material and Finish: Choose bolts with corrosion resistance or other properties suited to your application.

Common Questions about SAE Bolt Sizes

Q1: What does 1/4-20 mean on a bolt?

A: This indicates a bolt with a 1/4 inch diameter and 20 threads per inch.

Q2: Where can I find an SAE bolt size chart?

A: Charts are readily available online, in mechanic handbooks, and often printed on toolboxes.

Q3: What's the difference between SAE and metric bolts?

A: SAE uses inches for measurements, while metric uses millimeters. They are not interchangeable.

[Continue with additional questions and answers]

Tips and Tricks

- Use a thread gauge to quickly determine the thread pitch of a bolt.

- Keep a variety of SAE bolts and nuts organized in a labeled container.

- Invest in a torque wrench for precise tightening, especially in critical applications.

In conclusion, the seemingly simple SAE bolt size chart is a cornerstone of modern engineering and manufacturing. It represents the triumph of standardization, bringing order and efficiency to countless industries and projects. Understanding and utilizing this chart empowers us – from professional mechanics to weekend warriors – to tackle tasks with confidence, knowing that the right fastener is just a glance away. So, the next time you embark on a project, remember the power of this unassuming chart, and let it guide you to a job well done.

Riley farms fort smith ar a slice of arkansas charm

Silence the hate what are some comebacks for bullies

Toyota rav4 hybrid interior colors decoding the hues of hybrid heaven