Understanding Boat Impeller Replacement Expenses

Keeping your boat’s engine cool is crucial for smooth sailing. A vital component in this cooling system is the impeller, a rubber device that pumps water from the lake or ocean into the engine. Over time, impellers wear down and require replacement. Understanding the expense associated with this essential maintenance task – the boat impeller replacement cost – is key to responsible boat ownership.

The cost to replace a boat impeller isn't a fixed figure. Several factors influence the final price, including the make and model of your boat's engine, the specific impeller required, and labor charges if you choose professional installation. While the impeller itself might seem like a small part, neglecting its replacement can lead to significant engine damage, resulting in far greater expenses down the line. Thinking proactively about this relatively small expenditure can save you considerable money and hassle in the long run.

The impeller's function hasn't changed dramatically since its introduction. It remains the core component for circulating cooling water in most inboard and outboard engines. However, impeller materials have evolved, with modern impellers often made of more durable and flexible materials designed to withstand higher temperatures and resist wear. Despite these advancements, the importance of regular impeller changes remains unchanged. Just like any rubber component, it’s subject to deterioration due to heat, chemicals, and general use.

One of the primary concerns related to boat impeller replacement cost is the potential for unexpected expenses. While the impeller itself might be relatively inexpensive, additional issues can arise during replacement. For instance, a corroded housing or damaged pump components might require attention, adding to the overall cost. Careful inspection and proactive maintenance can help mitigate these unexpected costs by addressing potential problems early on. This underscores the importance of understanding not only the price of the impeller itself but also the potential for related expenses.

A typical boat impeller replacement cost can range from $20 to $100 for the part itself. Labor costs, if you're not doing the work yourself, can add another $50 to $150, depending on the complexity of the job and the mechanic's rates. Therefore, the total expense for a professional impeller replacement might range from $70 to $250. Factoring in the cost of additional parts if other components need attention, it’s wise to budget a bit more to avoid surprises. Regular inspection and maintenance can help you anticipate these potential extra costs and plan accordingly.

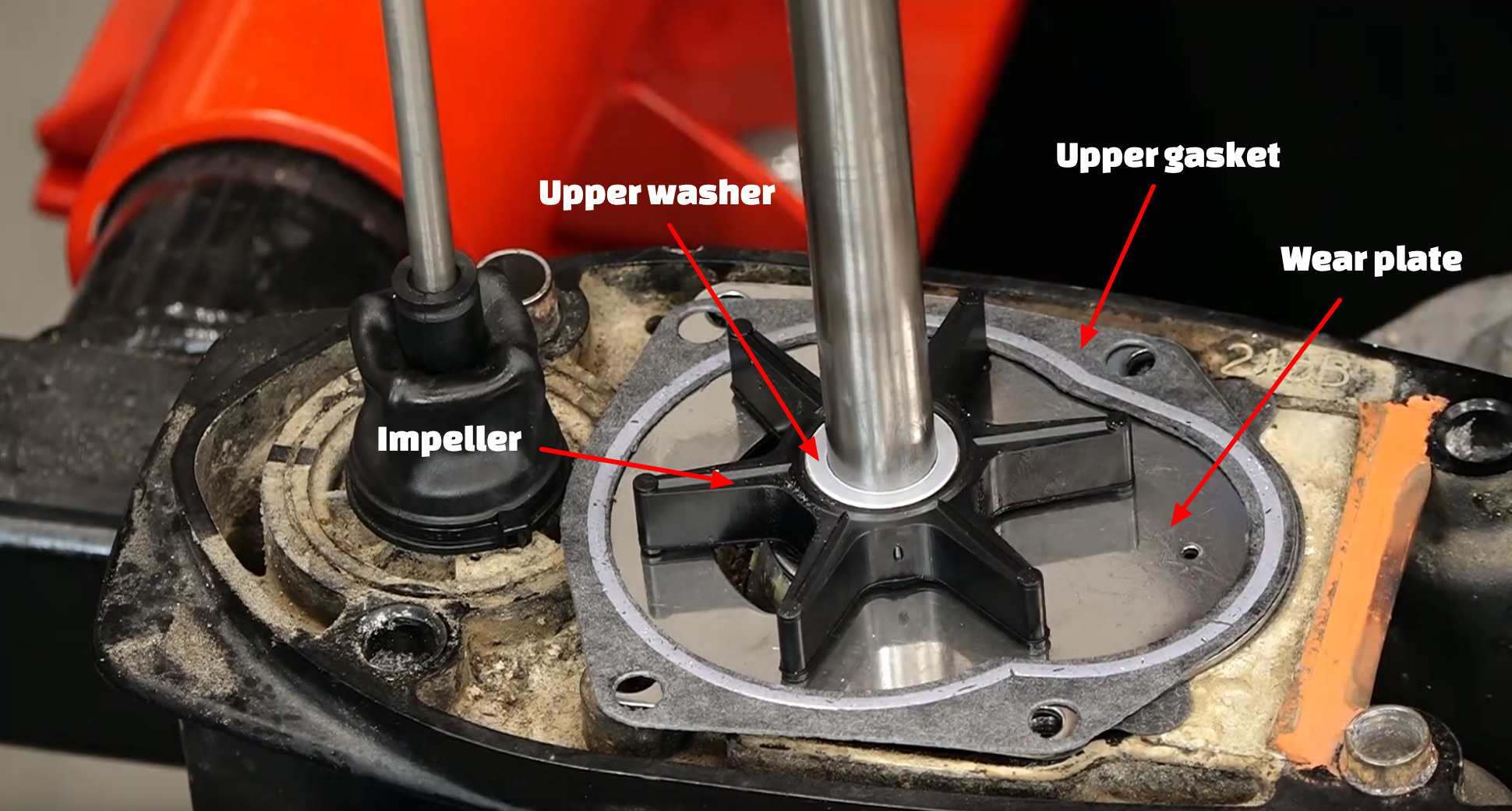

Replacing an impeller often involves removing the old impeller, inspecting the housing and other components for damage, lubricating the new impeller, and installing it correctly. Some boat owners opt for professional installation, while others prefer the DIY approach. Resources like online forums and instructional videos can provide guidance for those who choose to tackle the replacement themselves.

One benefit of timely impeller replacements is preventing engine overheating. A functioning impeller ensures proper cooling, safeguarding the engine from damage that could result in costly repairs. Another advantage is improved boat performance. A healthy cooling system contributes to efficient engine operation, leading to smoother running and better fuel economy. Finally, regular impeller changes offer peace of mind. Knowing that your engine's cooling system is in good working order allows you to focus on enjoying your time on the water.

Advantages and Disadvantages of DIY Impeller Replacement

| Advantages | Disadvantages |

|---|---|

| Cost savings on labor. | Risk of incorrect installation leading to further problems. |

| Increased understanding of your boat's systems. | Potential for additional costs if other parts are damaged during the process. |

| Convenience of performing the replacement at your own schedule. | Time commitment required for learning and performing the replacement. |

Best Practices for Impeller Replacement: 1. Inspect the impeller annually or every 50 hours of operation. 2. Always have a spare impeller on board. 3. Use a lubricant specifically designed for impellers during installation. 4. Carefully inspect the impeller housing for wear or damage. 5. Note the orientation of the old impeller before removing it to ensure correct installation of the new one.

Frequently Asked Questions: 1. How often should I replace my boat impeller? 2. What are the signs of a failing impeller? 3. Can I replace the impeller myself? 4. What type of impeller do I need for my boat? 5. Where can I buy a replacement impeller? 6. How much does a boat impeller cost? 7. How do I install a new impeller? 8. What tools do I need to replace an impeller?

In conclusion, understanding boat impeller replacement costs is a fundamental aspect of responsible boat ownership. While the cost itself is relatively modest, the implications of neglecting this crucial maintenance task can be significant. By being proactive, understanding the factors influencing the cost, and practicing regular maintenance, you can ensure smooth sailing and avoid potential headaches down the line. Investing in timely impeller replacements protects your engine, enhances your boat's performance, and gives you the peace of mind to enjoy your time on the water. Regular inspection, carrying a spare impeller, and understanding the replacement process, whether you choose DIY or professional service, are key elements of a well-maintained boat and a stress-free boating experience.

Unlocking affordable construction exploring prefab metal building kit pricing

Shine it up your guide to finding toon brite aluminum cleaner

Foundry lake havasu city az a deep dive