The Art of Wire Harness Installation

There’s a certain elegance to a perfectly routed wire harness, a quiet symphony of functionality hidden beneath the surface. Like a well-tailored garment, a properly installed wiring harness contributes to the overall performance and aesthetic of any system, from automobiles to aircraft. But achieving this seamless integration requires more than just connecting wires; it’s a craft demanding precision, patience, and a deep understanding of the underlying principles.

Wire harness installation is the process of strategically placing and securing a collection of wires bundled together, often within a protective sheath. This organized network acts as the nervous system of a machine, transmitting power and signals to various components. Imagine the chaos if these wires were simply strewn about – a tangled mess prone to shorts, malfunctions, and ultimately, system failure.

The history of wire harness installation is intertwined with the development of electrical systems themselves. Early electrical devices relied on simple, exposed wiring. As systems became more complex, the need for a more organized and protected wiring solution became evident. The development of insulated wires and bundling techniques led to the creation of the modern wire harness, a critical component in everything from early automobiles to the sophisticated electronics of today.

The importance of correct wire harness installation cannot be overstated. A poorly installed harness can lead to a cascade of problems, including short circuits, intermittent failures, and even fires. Furthermore, a messy harness makes troubleshooting and maintenance significantly more difficult, adding time and cost to repairs. Understanding the nuances of harness routing, securing, and connecting is crucial for ensuring the reliability and longevity of any electrical system.

One of the main issues encountered during wire harness installation is ensuring proper routing. The harness must be positioned in a way that avoids contact with sharp edges, moving parts, or excessive heat. Careful planning and consideration of the environment in which the harness will operate are essential. Securing the harness correctly is also vital, preventing movement and chafing that could damage the wires over time. Selecting the appropriate connectors and ensuring proper termination are equally important for maintaining a reliable electrical connection.

Installing a wire harness correctly offers several benefits. Firstly, it enhances the reliability of the system by minimizing the risk of electrical faults. Secondly, a well-organized harness simplifies maintenance and troubleshooting, saving valuable time and resources. Thirdly, a properly installed harness contributes to the overall aesthetic of the system, creating a clean and professional appearance.

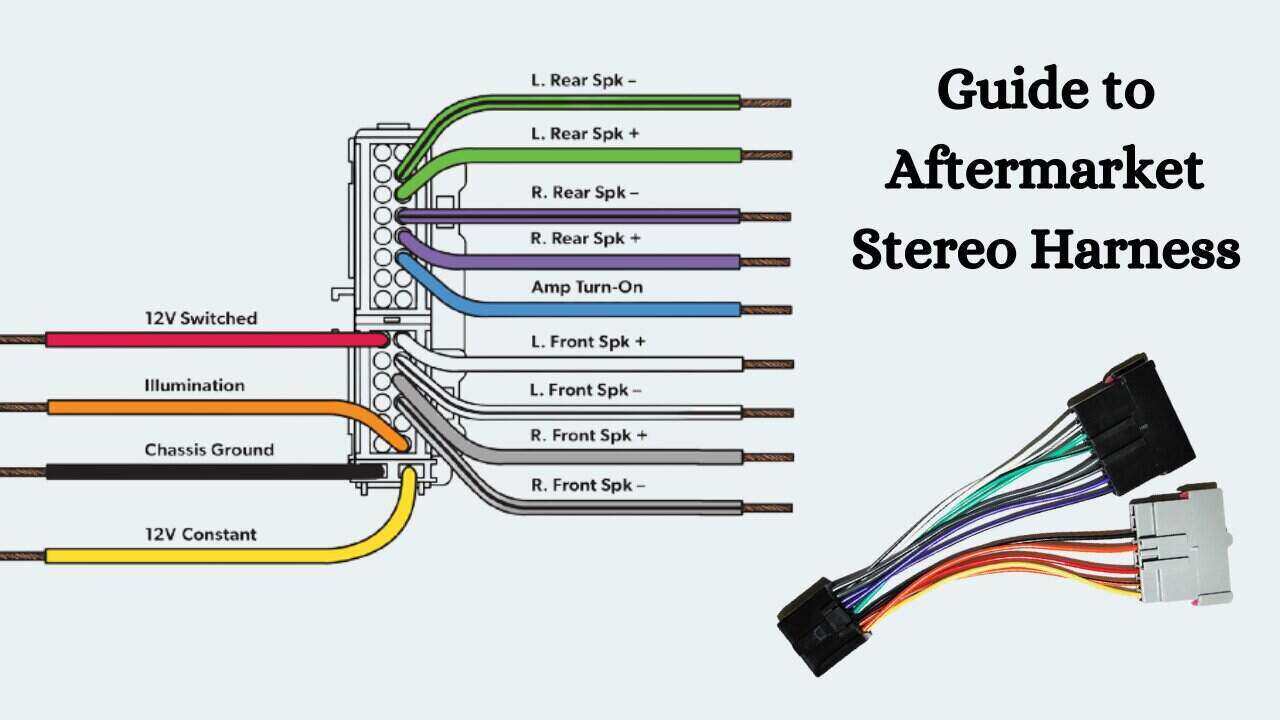

A typical wire harness installation process begins with planning the route and securing points. This often involves consulting diagrams and considering the physical layout of the system. Next, the harness is carefully routed and secured using appropriate clips, ties, or other fasteners. Finally, the wires are connected to their respective components, ensuring proper termination and insulation.

Before installing a wire harness, create a checklist: Verify you have the correct harness for the application, inspect the harness for any damage, gather the necessary tools (e.g., zip ties, connectors, crimping tool), and review the installation diagrams. During installation, double-check the routing, ensure secure fastening, and verify all connections.

Advantages and Disadvantages of DIY Wire Harness Installation

| Advantages | Disadvantages |

|---|---|

| Cost savings | Risk of improper installation |

| Increased understanding of the system | Time-consuming |

| Sense of accomplishment | Requires specialized tools |

Best Practices: 1. Plan the route carefully. 2. Use appropriate securing methods. 3. Ensure proper termination of wires. 4. Protect the harness from environmental factors. 5. Test the system thoroughly after installation.

Real-world examples of wire harness installations can be found in automotive wiring, aircraft wiring, and industrial machinery wiring.

Challenges can include tight spaces, complex routing, and specialized connectors. Solutions involve using flexible conduit, angled connectors, and specialized crimping tools.

FAQ: 1. What tools are needed? 2. How do I choose the right harness? 3. How do I route the harness? 4. How do I secure the harness? 5. How do I terminate the wires? 6. How do I troubleshoot problems? 7. What safety precautions should I take? 8. Where can I find more information?

Tips and tricks: Use color-coded wires for easy identification. Label wires for future reference. Use heat shrink tubing to protect connections.

In conclusion, wire harness installation is a critical aspect of building and maintaining reliable electrical systems. A well-executed installation ensures optimal performance, simplifies maintenance, and enhances the overall aesthetic. From the intricate wiring of a performance vehicle to the complex systems of an aircraft, the art of wire harness installation plays a vital role in ensuring functionality and safety. While it might seem like a daunting task, understanding the principles and following best practices can empower anyone to confidently tackle a wire harness installation project. Invest the time to plan, prepare, and execute meticulously, and you'll reap the rewards of a robust and elegant electrical system. This meticulous approach not only ensures a functional system, but also reflects a commitment to quality and attention to detail that elevates the entire project. So, embrace the challenge, and master the art of the perfectly installed wire harness.

Unlocking childhood memories the magic of lilo and stitch disney junior intro

Unlocking the power of cody rhodes visuals a guide to his iconic imagery

Unlocking growth navigating the landscape of bonuses subject to eis