Decoding the Mysteries of the Fuel Sending Unit Bench Test

Ever glanced at your fuel gauge and wondered about the magic behind its seemingly simple function? That little needle, dancing between "E" and "F," relies on a crucial component: the fuel sending unit. And ensuring its accuracy often involves a process called a bench test. But what exactly is a fuel sending unit bench test, and why should you care?

A fuel sending unit bench test is essentially a controlled examination of the fuel sending unit outside of its natural habitat—the fuel tank. It involves simulating the conditions inside the tank to verify the unit's performance and accuracy. This process helps diagnose faulty readings, ensuring your gauge reflects the actual fuel level, preventing unexpected stops and potential damage to the fuel pump.

Imagine a scenario: you're on a road trip, miles from civilization, and your fuel gauge suddenly plummets to empty, despite filling up just hours ago. This could be a classic symptom of a malfunctioning sending unit. A bench test could have preemptively identified this issue, saving you from a roadside emergency. This is just one example highlighting the importance of understanding and utilizing this diagnostic procedure.

The history of fuel sending units is intertwined with the evolution of automobiles. As cars transitioned from rudimentary fuel level indicators to more sophisticated systems, the sending unit became a critical component. Early versions were simple float-based mechanisms, while modern units often incorporate more complex electronic components. The evolution of these units underscores the need for accurate testing procedures like the bench test.

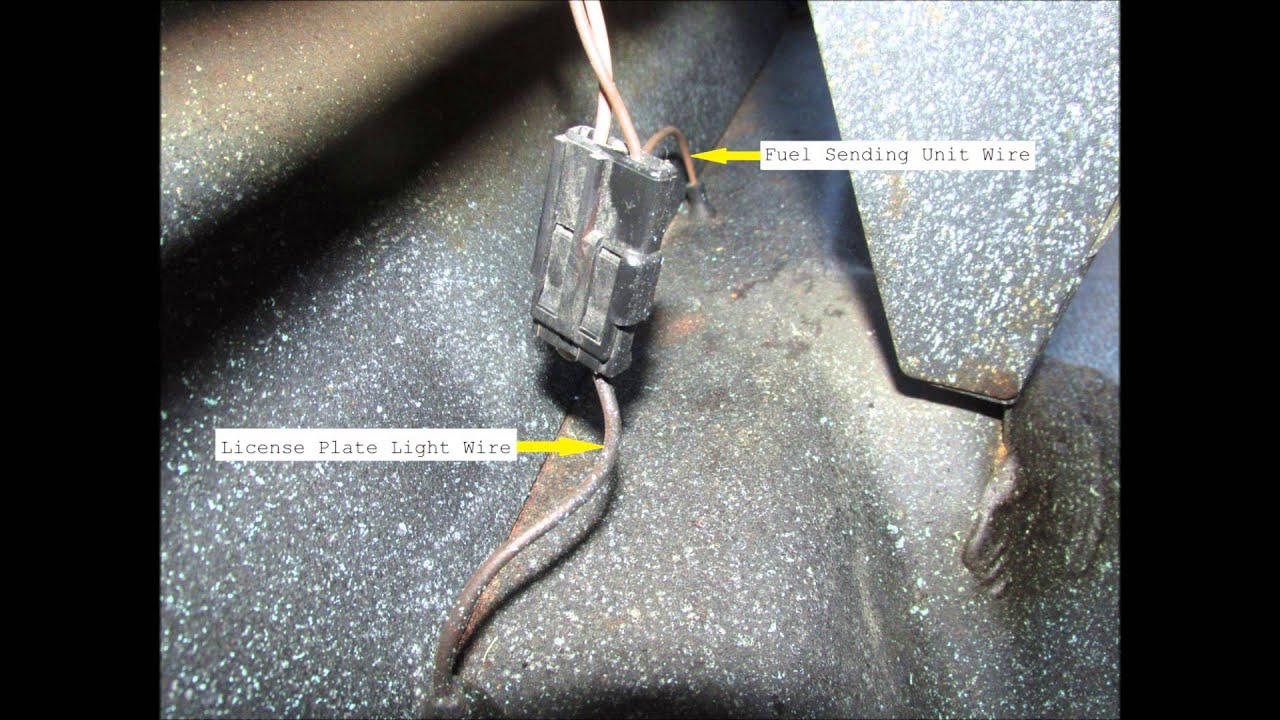

The core function of a fuel sending unit is to measure the fuel level within the tank and transmit this information to the fuel gauge. Testing this function outside the tank allows for precise measurements and adjustments without the complexities of working within a confined space. Common issues detected during bench testing include faulty float mechanisms, damaged wiring, and resistance inconsistencies, all of which can lead to inaccurate fuel readings.

One key benefit of bench testing a fuel sending unit is the ability to isolate the problem. By removing it from the vehicle, you eliminate other potential variables that might affect the fuel gauge reading, like wiring issues external to the unit itself. This focused approach allows for more accurate diagnostics.

Another advantage is the ease of troubleshooting. With the unit accessible on a workbench, technicians can manipulate and examine it more easily, identifying the root cause of the problem and making necessary adjustments or repairs more efficiently than if it were still installed in the vehicle. This accessibility also simplifies the testing process, making it quicker and more cost-effective.

A third benefit is the prevention of further damage. A malfunctioning fuel sending unit can sometimes lead to issues beyond inaccurate readings. For instance, a continuously incorrect low-fuel reading can cause the fuel pump to run dry, potentially leading to pump failure. Bench testing can help identify these issues early on, preventing costly repairs down the line.

Here’s a step-by-step guide to conducting a basic fuel sending unit bench test:

1. Disconnect the sending unit from the vehicle.

2. Connect the sending unit to an ohmmeter.

3. Move the float arm through its full range of motion.

4. Observe the ohmmeter readings and compare them to the manufacturer’s specifications.

5. Any deviation from the specified resistance range indicates a potential issue.

Advantages and Disadvantages of Bench Testing a Fuel Sending Unit

| Advantages | Disadvantages |

|---|---|

| Isolates the problem | Requires removal of the unit |

| Easier Troubleshooting | Requires specialized equipment (ohmmeter) |

| Prevents Further Damage | May not replicate all in-vehicle conditions |

Best Practices for Bench Testing a Fuel Sending Unit:

1. Always consult the vehicle's service manual for specific testing procedures and resistance values.

2. Use a high-quality ohmmeter to ensure accurate readings.

3. Carefully move the float arm to avoid damage.

4. Inspect the unit for any physical damage or corrosion.

5. Document your findings for future reference.

FAQs:

1. Q: What is a fuel sending unit? A: It's a device that measures the fuel level in your tank and sends that information to the fuel gauge.

2. Q: Why should I bench test a fuel sending unit? A: To verify its accuracy and diagnose potential issues.

3. Q: What equipment do I need for a bench test? A: An ohmmeter.

4. Q: What are common problems found during bench testing? A: Faulty float, damaged wiring, resistance inconsistencies.

5. Q: How can I prevent fuel sending unit problems? A: Regular maintenance and inspections.

6. Q: What are the signs of a faulty fuel sending unit? A: Inaccurate fuel gauge readings, erratic needle movement.

7. Q: How often should a fuel sending unit be tested? A: As needed or when suspected of malfunctioning.

8. Q: Can I replace a fuel sending unit myself? A: Yes, but it can be a challenging task requiring some mechanical knowledge.

In conclusion, the fuel sending unit bench test, while often overlooked, is a vital diagnostic procedure. It empowers car owners and mechanics to pinpoint issues related to inaccurate fuel gauge readings, preventing frustrating breakdowns and potentially costly repairs. Understanding the benefits, the process, and the best practices of fuel sender testing ensures accurate fuel readings, contributing to a smoother, more reliable driving experience. By mastering this seemingly small aspect of car maintenance, you're taking a significant step toward maintaining the overall health and longevity of your vehicle. Don't underestimate the power of this small but mighty component—it plays a crucial role in keeping you on the road and reaching your destination without unexpected fuel-related surprises. Take the time to learn about your fuel system, and you'll be rewarded with a more dependable and enjoyable driving experience.

The subtle art of mechanical pencil resurrection a guide to fixing your papermate

Unlocking opportunities mastering the art of surat permohonan kunjungan ke perusahaan

Wells fargo bank class action lawsuits a guide for consumers