Decoding the Enigma: Mastering Your Fuel Gauge and Sender

There's a certain quiet confidence in knowing your vehicle inside and out. It's akin to the perfectly tailored suit – understanding the mechanics beneath the surface allows you to navigate any situation with grace. Today, we delve into the often-overlooked, yet crucial, duo: the fuel gauge and sender. Understanding their function and how to diagnose issues can save you from unexpected roadside stops and maintain the seamless flow of your journey.

Imagine this: you're cruising down a scenic highway, lost in the rhythm of the road, when suddenly, the fuel gauge plummets to empty. Panic sets in. Are you truly stranded, or is it a mere phantom reading? This is where the knowledge of fuel gauge and sender testing becomes invaluable. A preemptive check can avert such anxieties, ensuring your travels remain uninterrupted.

The fuel gauge and sender system is relatively simple in concept: the sender, a float-activated potentiometer located in the fuel tank, measures the fuel level. This measurement is then transmitted to the gauge on your dashboard, giving you a visual representation of the remaining fuel. However, the simplicity of the system belies the potential for complications. Corrosion, wiring issues, or a faulty gauge can lead to inaccurate readings, potentially leaving you stranded.

Testing the fuel gauge and sender involves checking the integrity of the entire system, from the wiring to the gauge itself. It's a process akin to inspecting the stitching of a finely crafted garment, ensuring every element is in its rightful place and functioning as intended. This guide will equip you with the knowledge to perform these tests, providing you with the autonomy to maintain your vehicle's reliability.

Checking your fuel gauge and sender doesn't require a mechanic's expertise. With a few basic tools and a methodical approach, you can diagnose and potentially fix the issue yourself. Think of it as tailoring your own experience, taking control of your vehicle's performance and ensuring a smooth, uninterrupted ride.

The history of fuel gauges goes back to the early days of automobiles. Initially, simple float systems were used, later evolving into the more sophisticated electronic systems we see today. Accurate fuel measurement is vital for obvious reasons – preventing running out of fuel, managing fuel consumption, and ensuring a worry-free driving experience. Common issues include a faulty sending unit, a malfunctioning gauge, or wiring problems. These issues can lead to inaccurate readings, making it difficult to gauge remaining fuel.

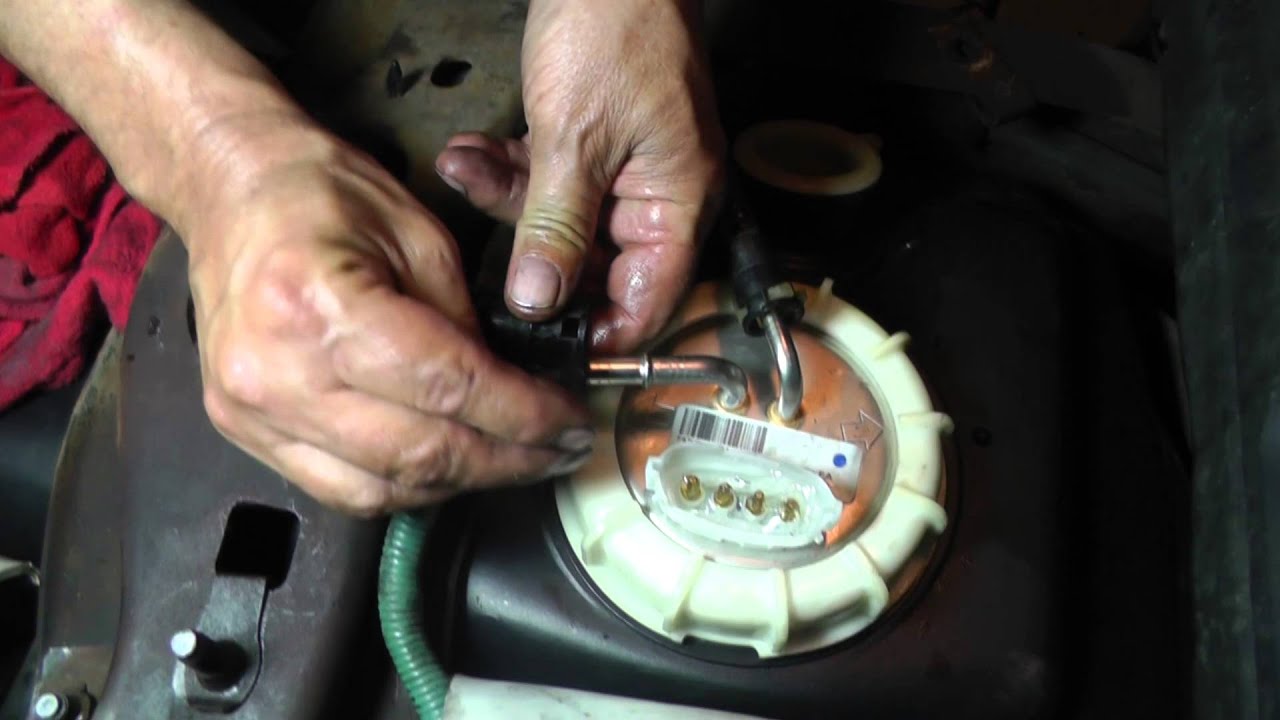

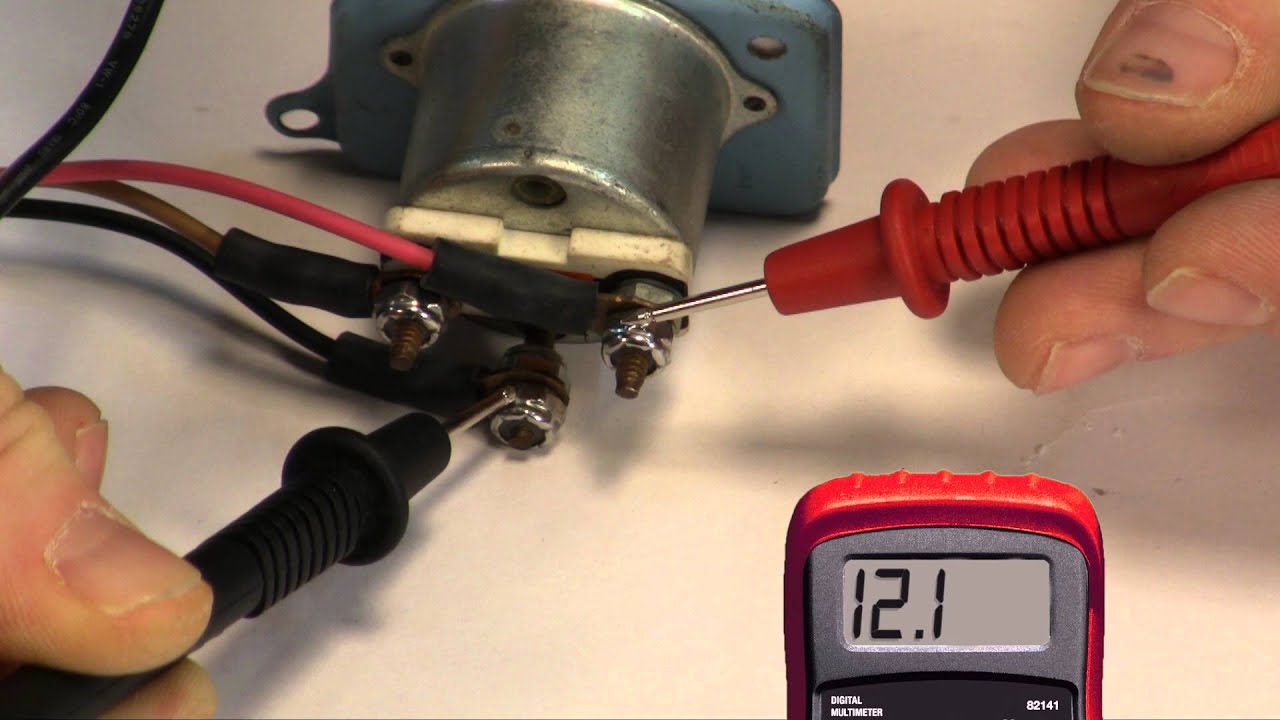

One simple test involves turning the vehicle's ignition to the "on" position without starting the engine. Observe the fuel gauge. It should move to its designated position based on the fuel level in the tank. If it remains unresponsive or displays erratic behavior, it suggests a potential issue within the system. Another method involves directly testing the sender unit with a multimeter, measuring the resistance at varying fuel levels. This requires accessing the sender unit, often located beneath the rear seat or through an access panel in the trunk.

Benefits of testing your fuel gauge and sender include: preventing unexpected fuel outages, accurate fuel consumption monitoring, and early detection of potential issues, saving on costly repairs down the line. For example, identifying a faulty sender early on can prevent further damage to other components of the fuel system.

A step-by-step guide includes: 1) Checking the fuel gauge with the ignition on. 2) Visually inspecting the wiring and connections for damage. 3) Testing the sender unit with a multimeter. 4) Consulting the vehicle’s service manual for specific testing procedures.

A simple checklist: Fuel gauge responsiveness, wiring condition, sender unit resistance, and fuse integrity.

Advantages and Disadvantages of DIY Fuel Gauge/Sender Testing

| Advantages | Disadvantages |

|---|---|

| Cost savings | Potential for misdiagnosis |

| Early problem detection | Requires some technical knowledge |

Five Best Practices: 1. Consult your vehicle’s service manual. 2. Use the correct tools and safety precautions. 3. Document your findings. 4. If unsure, seek professional assistance. 5. Regularly inspect the fuel system components.

FAQ's: How often should I test? What tools do I need? What if my gauge is stuck? What are the symptoms of a bad sender? etc. (Add more FAQs and answers).

Tips and Tricks: Observe the fuel gauge behavior when filling the tank. Note any inconsistencies. Check for fuel leaks around the tank area. Keep the fuel tank above a quarter full to prevent sediment buildup affecting the sender.

Mastering the art of fuel gauge and sender testing empowers you with a deeper understanding of your vehicle's intricate workings. It's about more than just avoiding a breakdown; it's about cultivating a connection with your machine, anticipating its needs, and ensuring a smooth, confident journey. Just as a well-tailored suit complements your personal style, understanding your vehicle's mechanics adds a layer of refinement to your driving experience. By taking the time to diagnose potential fuel system issues, you’re not just preventing a roadside emergency, you’re investing in the longevity and reliability of your vehicle, ensuring every journey is undertaken with confidence and style. Don't hesitate to explore the resources available – online forums, repair manuals, or a trusted mechanic – to enhance your understanding and refine your approach. Embrace the challenge, and enjoy the satisfaction of a well-maintained machine.

Document collection authorization the ultimate guide

Word font size shortcuts conquer text formatting like a pro

Unlocking the elegance of traditional malay attire